Choosing the right laser cutting machine for your business can feel like a daunting task, but with the right information, you can make an informed decision that suits your needs perfectly.

Whether you’re venturing into laser cutting for the first time or upgrading your current equipment, there are several key factors to consider.

Understanding Your Business Needs

Understanding your business needs is the first crucial step in choosing the right laser cutting machine. You need to thoroughly assess the production volume by determining how frequently you’ll use the machine and the scale of your cutting tasks.

It’s essential to identify the types of materials you will be working with, such as metals, plastics, or wood, and their respective thicknesses, as different machines cater to different material requirements.

Additionally, consider the precision and quality standards you need for your projects; some businesses demand high precision for intricate designs, while others might prioritise speed over fine details.

Types of Laser Cutting Machines

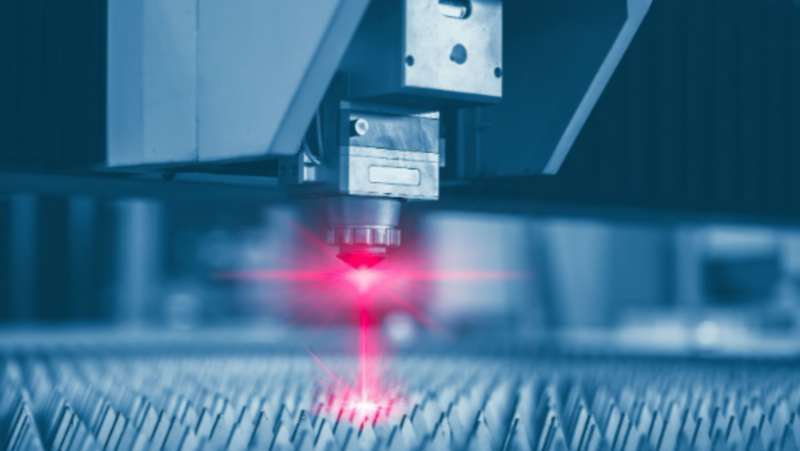

When choosing a laser cutting machine, it’s essential to understand the different types available and their respective advantages.

Carbon dioxide (CO2) laser cutting machines are highly versatile, making them ideal for non-metal materials such as wood, acrylic, and glass.

Fibre laser cutting machines, on the other hand, are tailored for metal cutting, excelling with materials like steel, aluminium, and brass.

Nd laser cutting machines are known for their exceptional precision and are used for both metal and non-metal applications, though their high cost often limits them to specialised tasks.

Budget and Cost Considerations

When evaluating budget and cost considerations for a laser cutting machine, it’s important to balance the initial investment with the long-term value.

While the upfront cost of a high-quality machine might be substantial, investing in a reliable and efficient model can lead to significant savings over time through reduced maintenance, higher productivity, and longevity.

Consider the ongoing expenses, such as maintenance, repairs, and consumables like lenses and gases, as these can add up and impact your overall budget.

Manufacturer Reputation and Support

Considering the manufacturer’s reputation and support services is crucial when choosing a laser cutting machine, as these factors significantly influence the machine’s reliability and your overall experience.

Start by researching the manufacturer’s history and standing in the industry; brands with a solid reputation such as Simply Plastics typically have a proven track record of producing durable, high-performance machines.

Customer feedbacks and testimonials can offer valuable insights into the real-world performance and dependability of the machine.

A responsive and knowledgeable support team can make a significant difference, especially when troubleshooting issues or learning to use new equipment.

Ultimately, the right choice should align with your production goals, material requirements, and financial plans, ensuring that the machine you select will enhance efficiency, productivity, and profitability in your business operations.

Choosing the right laser cutting machine for your business involves careful consideration of various factors, from your specific business needs to the machine’s features and costs.

By taking the time to evaluate your options thoroughly, you can find a machine that enhances your production capabilities and supports your business growth.