The world of modern dentistry is transforming, and at its heart are Dental Milling Machines, now increasingly found in dental offices rather than exclusively in external labs. This shift from centralized lab production to chairside fabrication is reshaping workflows, patient experiences, and practice economics. In-office milling brings opportunities for speed, control, and customization right into the treatment room. As more practices adopt these systems, it’s becoming a defining trend of contemporary dental care.

Why the Shift to In-Office Milling Is Accelerating

Dental practices have long relied on external labs for fabricating crowns, bridges, and implants, but that model often involves waiting days or weeks. The move toward in-office milling addresses this lag by enabling dentists to produce restorations while the patient waits, dramatically reducing turnaround time. Furthermore, with digital intraoral scanners integrating seamlessly into these systems, the entire process—from scanning to milling—can now happen in-house.

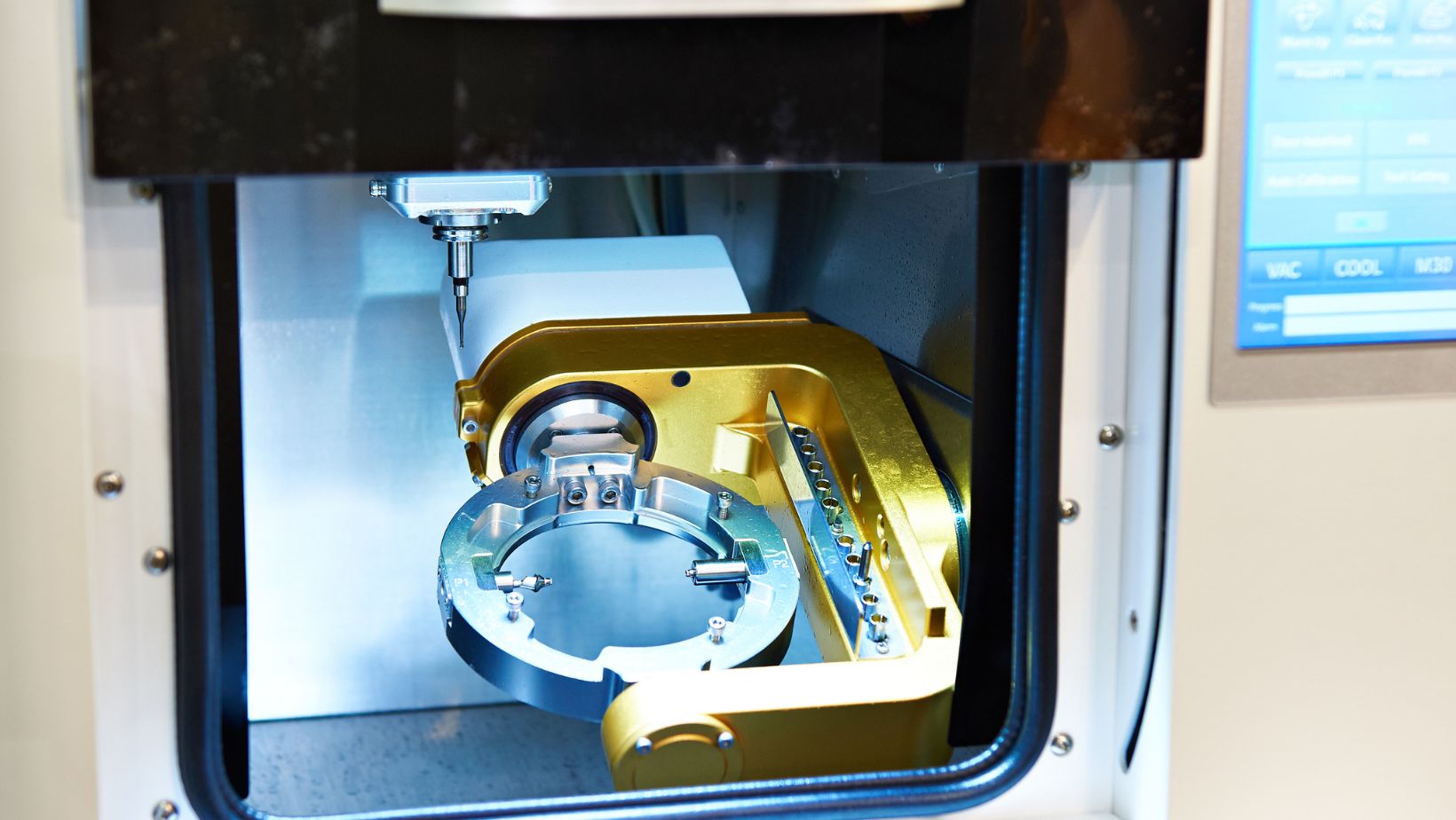

Another key driver is the improvement in milling machine precision and reliability. Early systems were bulky, expensive, and limited in material choice, but today’s models are compact, faster, and capable of handling zirconia, lithium disilicate, composites, and even hybrid materials. This range allows dentists to offer a full suite of restorative options without compromising on quality.

Cost dynamics are also influencing the trend. While the upfront investment in an in-office milling system is non-trivial, the savings from outsourced lab fees and turnaround inefficiencies render it economically viable over time. Practices that adopt milling machines can better control pricing, reduce lab markups, and pass savings—or reinvested quality—onto patients.

How In-Office Milling Enhances Patient Experience

A fundamental advantage of chairside fabrication is the time saved. Patients no longer need to return for multiple appointments or wear temporary crowns while waiting for lab work. In a single visit, scanning, designing, and milling can be completed, giving them a finished restoration that fits precisely and looks natural. That immediacy improves satisfaction and reduces appointment fatigue.

Beyond speed, personalization has become more achievable. Tooth-shade matching, occlusal adjustments, and fine aesthetic modifications can be done on the spot, guided by the digital workflow. This flexibility ensures that restorations are tailored closely to each patient’s needs, enhancing both function and appearance.

Seeing technology in action also has a psychological impact. Patients are often impressed by modern equipment, which allows them to mill a crown while they wait. This transparency builds confidence and reinforces the practice’s reputation for innovation. It turns what used to be abstract lab work into a tangible, reassuring experience.

Practical Considerations for Dental Practices

Integrating an in-office milling machine isn’t as simple as plugging it in. Staff training is vital: dental teams need to learn scanning protocols, software operation, and material handling. Proper training ensures efficiency and reduces errors, so practices often enroll in manufacturer-led workshops or partner with experienced trainers.

Space and workflow must also be considered. Even compact milling units require proper ventilation, dust control, and proximity to design stations. Practices may need to reconfigure operatories or dedicate a small design-to-mill suite to maintain hygiene and operational flow. Collaboration between dentists, assistants, and lab technicians (where applicable) is key to seamless implementation.

Lastly, material inventory and maintenance are ongoing factors. Milling units consume blanks and burs that need regular restocking, and the machines themselves require routine calibration and cleaning. Practices must budget for recurring costs and establish protocols for preventive maintenance to avoid downtime and ensure consistent quality.

Technological Innovations Fueling the Trend

Advances in CAD/CAM (computer-aided design/computer-aided manufacturing) platforms are core to the rise of in-office milling. Software has become more intuitive, allowing dentists to design crowns and bridges with guided workflows, minimal training, and integrated restorative libraries. Realistic rendering tools help clinicians visualize final outcomes before fabrication begins.

Automation features have also matured: automatic blank-centering, toolpath optimization, and real-time milling feedback reduce operator intervention and user error. Some systems now include automated tool changes and debris management, decreasing the time spent on manual tasks and increasing throughput.

Looking forward, integration with AI and predictive analytics is on the horizon. AI-assisted shade matching, margin detection, and design optimization promise even greater speed and precision. Practices that adopt future-ready milling systems may soon benefit from suggestions on design parameters and automatic justification of material use—further streamlining chairside restorative workflows.

The Impact on Dental Laboratories

It’s no surprise that as more offices bring milling in-house, dental labs face pressure to redefine their roles. Labs are pivoting toward high-end specialty services such as complex implant cases, full-arch restorations, and hand-stained cosmetic work that still benefit from artistry and traditional craftsmanship. They are also increasingly positioning themselves as partners, offering manuals, training, and materials to collaborating offices.

Rather than disappear, many labs now act as regional support hubs, supplying milling blanks, consulting on designs, or offering finishing touches to clinic-milled restorations. This hybrid model allows labs to maintain relevance while supporting clinics that choose to keep fabrication local.

Some laboratories are even adopting in-office milling themselves, offering “satellite” services anchored in practices—shifting from fabrication-centric roles to logistics managers, educators, and designers. This evolution underscores that while technology disrupts, collaboration remains a cornerstone of quality patient care.

Conclusion

In-office dental milling machines are redefining restorative workflows, bringing efficiency, personalization, and technological gravitas directly into the treatment room. From reducing turnaround times to enhancing patient confidence, chairside milling empowers practices to deliver superior results with greater control. Success depends not just on technology, but on training, workflow design, and collaboration—both internally and with evolving laboratory partners. As CAD/CAM software, machine automation, and AI integrations continue to advance, the laboratory-to-chairside model is poised not just to grow, but to become the standard for modern restorative dentistry.